- Keyboards[112]

- Pipe Fittings[18]

- Valves[10]

- Chinese Snack[3]

- Contact Person : Ms. Wang Yoki

- Company Name : Yuhuan World Copper Co., Ltd.

- Tel : 0086-576-87111617

- Fax : 0086-576-87111688

- Address : Zhejiang,Taizhou,Hexin Industrial Zone, Qinggang, Yuhuan,Zhejiang

- Country/Region : China

- Zip : 317606

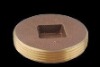

Special Bronze Ball Valve WD-2112

Detailed Product Description

Special Bronze Full Port Ball Valves with Threaded Ends.WD-2112

-Full-port design

-Bronze body

-Chrome plated machined brass rod ball

-Adjustable packing nut

-2 Non-sticking teflon seats

-Latch locking handle or Extended lever handle.

-Orange non-heating plastic coat

-100% air tested under water

-600lb. WOG (water, oil and gas)

-Working pressure: 150lb. saturated steam

-Teflon packing for safety against leakage around stem

-Rugged body and blowout proof stem construction.

.

| G | DN(mm) | APPROX.W(G) | BOX/CTN | FOB/CNF PRICE |

| 3/4" | 20 | 510 | ||

| 1" | 25 | 805 | ||

| 1 1/4" | 32 | 1270 | ||

| 1 1/2' | 40 | 1660 | ||

| 2" | 50 | 2480 |

.

| PART | SPECIFICATION |

| Handle | Zinc Plated Steel Clenr Chromate Plastisol Coated |

| Handle Nut | Zinc Plated Steel |

| Packing Gland | Brass ASTM B 16 Alloy C36000 |

| Packing | TFE |

| Thrust Washer | Reinforeed TFE |

| Stem | Silicon Bronze ASTM B 371 Alloy C69400 or ASTM B 16 Alloy C3600 |

| Seat Ring(2) | Reinforeed TFE |

| Ball | Brass ASTEM B 124 Alloy C37700 or ASRM B 16 Alloy C36000 with Hard Chrome Plate |

| Main Body | Bronze ASTM B 584 Alloy C84400 |

| Coupling | ASTM B 124 Alloy C37700 |

| Check Valve Body | Bronze ASTM B 584 Alloy C84400 |

| Soft Disc | Buan-N |

| Disc Holder | Stainless Steel Type 301 |

| Spring | Stainless Steel ASTM A 276 Type 316 |

| Seat Screw | Stainless Steel ASTM A 276 Alloy S43000 |

| Valve stem | Stainless Steel ASTM A 582 Alloy C30300 |

.

This Conventional Port Bronze Ball Valve may be used for general purpose or utility service application . Cast bronze body and end piece, blowout proof silicon bronze stem or 316 stainless steel ball and stem are optional(66 Trim) NPT threaded ends are standard. Solder end valves also available .When installing solder end valves , conventional soldering techniques should be used.

The latch lock mechanism installed on the lever secures the valve in either the open or closed position.A padlock can be installed locking the valve in open or closed position.